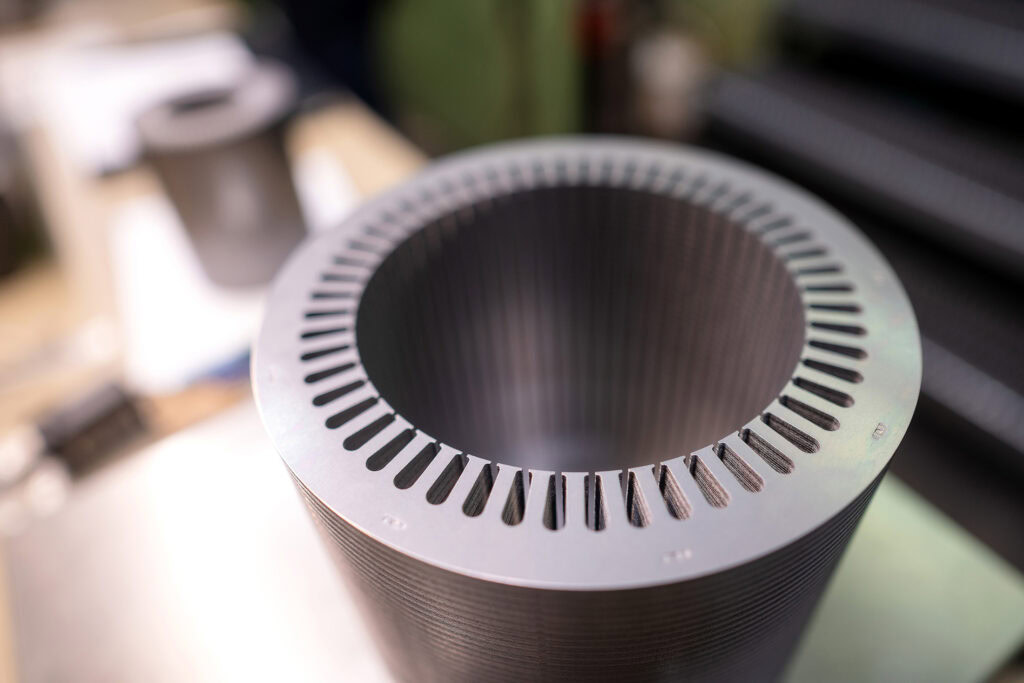

Game-changing innovation

Oberg introduced tungsten carbide stamping dies in 1948. The first rotor-stator lamination dies in 1950. And interlocked dies in 1980. Today, we continue to be an industry leader in dies, die components and automation systems using precision tooling for a wide range of markets. Our latest innovation is a die try-out cell where we produce tooling for EV/HEV motor components.

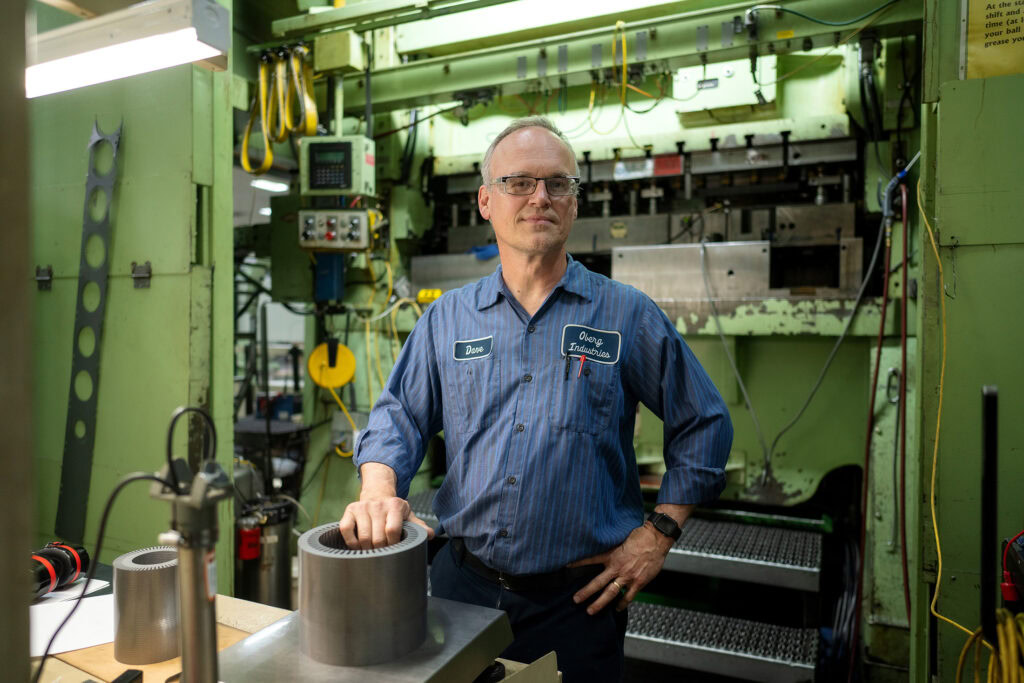

Superior talent

With over 25 die engineers, 10 automation engineers and 500 skilled machinists, surface grinders and technicians, our team has the diverse expertise to design and manufacture any die package. We keep up the good work by continuously developing and training new employees with our nationally recognized apprentice program.

Exceptional value

Oberg maintains an internal carbide lab, where we work closely with you to insure the best carbide selection, material performance and total value for each application. Our tooling expertise helps you achieve a low total cost of ownership — quite often even a lower cost alternative to fine blanking a part.