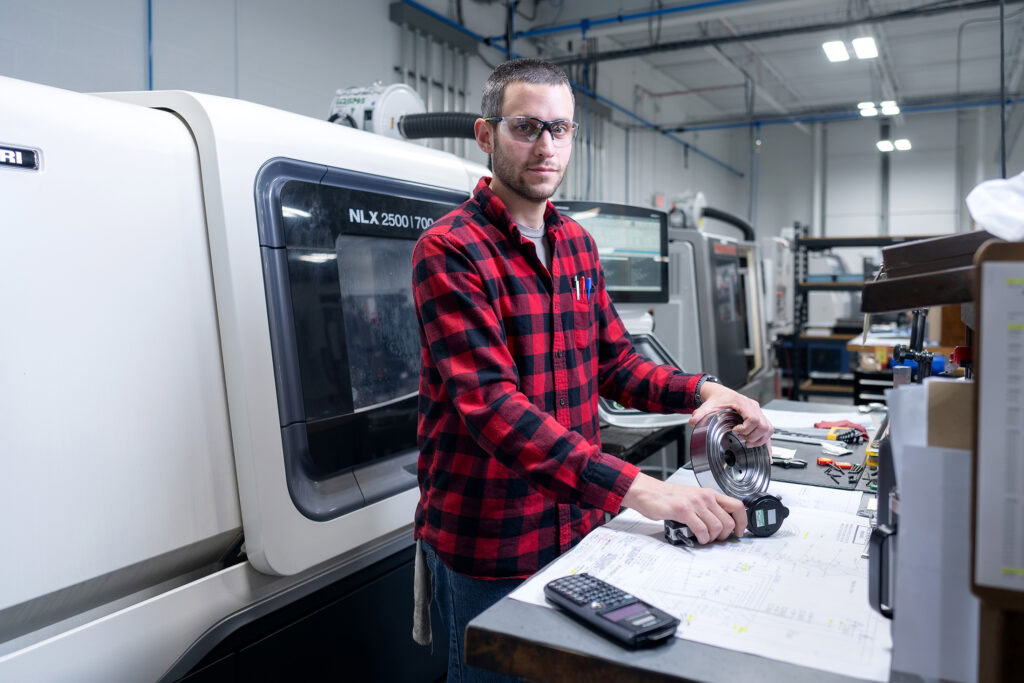

Our strength lies in the people behind the tooling. With decades of experience, rigorous training, and advanced manufacturing technology, we bring customer-provided designs to life with unmatched precision. From Cupper Press and Bodymaker Tooling to Necker and Conversion Tooling, we support nearly every stage of the can-making process. If you need a specialized solution, our team is ready to collaborate and deliver tooling that meets your exact production requirements.

Click on the specific metal packaging tooling below to learn more.

CAN TOOLING

Cupper Tooling

Body Maker Punches

Body Maker Tooling

Draw Redraw Tooling

Necker Tooling

END TOOLING

Shell Tooling

Curler Tooling

Rivet & Tab Tooling

Machining/Turning/EDM

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

- Hard Turning Lathes

Precision Grinding

- Wave Shear Grinding

- Surface / Centerless

- Jig / Advanced MDP®

- Lapping

- OD/ID

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide (Nickel, Cobalt)

- Alloy Steel (Stainless, Nickel, Tool Steel)

- Carbon Steel

- Ceramics

- Aluminum

- Powdered Tool Steels (CPM, M4, ASP)

Beverage Can Tooling

CAN BODY FORMING TOOLING

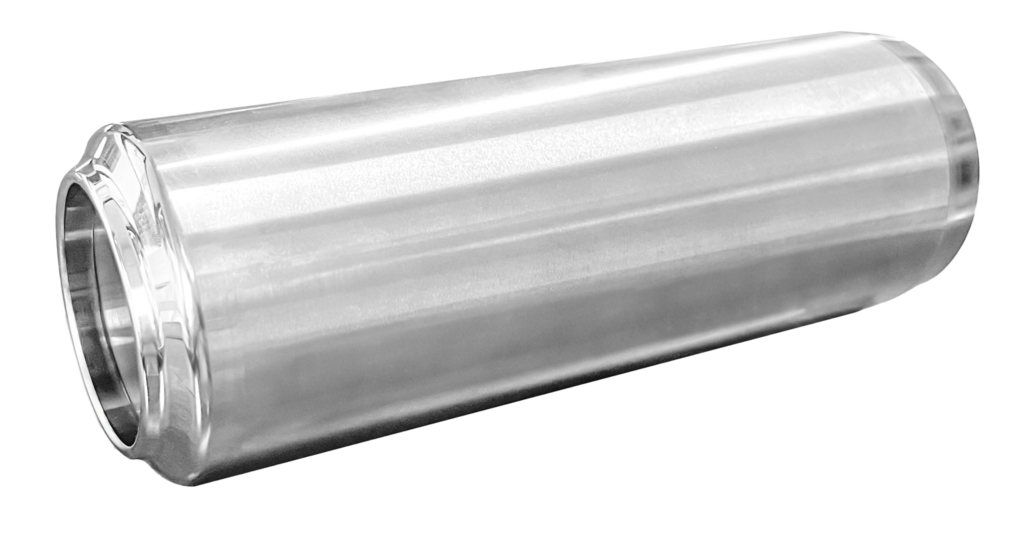

- Cupper Tooling: Can body forming begins by blanking aluminum sheets and forming them into shallow cups, establishing the foundation for precise can shaping. It utilizes punches, blank and draw dies, and draw pads to ensure uniformity, with scrap choppers managing excess material to maintain efficiency.

- Body Making Tooling: This tooling extends shallow cups into cylindrical can-bodies using punches, redraw sleeves, and ironing dies. These components work together to achieve consistent wall thickness, precise dimensions, and structural strength, ensuring durability throughout production.

- Necker Tooling: Shapes the top of the can body to form a precise neck using dies, spin rollers, and curl/flange tooling. This precision ensures the neck matches lid specifications for a secure fit and maintains consistent can performance.

- End Tooling: Transforms pre-formed shells into fully functional can ends by adding features such as tabs, rivets, and scoring for easy opening. The process includes curling and forming to ensure a secure fit and reliable sealing for beverage containers.

- Curler Tooling: Shapes the edges of can components, such as the top or bottom of the can body and the can ends, by curling the material to create a smooth, rounded edge. This process prepares the edges for seaming, ensuring they are formed correctly for a tight, secure fit when the can is assembled.

- Seaming Tooling: Joins the can body and ends by curling and compressing them to form a tight, secure seal. It ensures a precise fit and durable connection, maintaining the integrity of the beverage container and preventing leaks or contamination.

Materials Optimized for Beverage Can Tooling

Beverage can manufacturing demands tools that deliver unmatched speed, precision, and consistency. Oberg Industries’ beverage can tooling solutions are crafted from materials engineered to excel in high-performance environments.

TUNGSTEN CARBIDE BEVERAGE CAN TOOLING

- Ideal for High-Volume Runs: Known for its exceptional wear resistance, tungsten carbide ensures consistent performance and extended tool life during high-speed operations.

TOOL STEEL BEVERAGE CAN TOOLING

- Adaptable Performance: Offers a variety of grades to handle the precise cutting, forming, and shaping needs of beverage can production.

- Grade Highlights:

- A2 Tool Steel: Versatile for general cutting and forming.

- D2 Tool Steel: Provides exceptional wear resistance for demanding processes.

- S7 Tool Steel: Ideal for tooling subject to repeated impact.

- H13 Tool Steel: Heat-resistant for hot forming operations.

- Powdered Tool Steels: Excellent for high-stress applications, offering durability and versatility.

CERAMIC BEVERAGE CAN TOOLING

- Precision Under Pressure: Ceramic materials excel in high-temperature and corrosion-resistant applications, maintaining tool accuracy and quality over time.

Key Considerations for Beverage Can Tooling

Precision and speed define the beverage can industry, requiring tooling solutions that can handle high production rates while maintaining accuracy. Oberg delivers tooling designed to:

- Accommodate Precision Dimensions: Ensuring each can meets the exacting standards of beverage packaging.

- Sustain High-Output Demands: With materials and designs that minimize wear and extend production cycles.

- Optimize Material Usage: Tools are engineered to maximize efficiency and reduce material waste.

Why Partner with Oberg Industries for Beverage Can Tooling?

Our tooling solutions for beverage can manufacturers are crafted to provide a competitive edge:

- Proven Expertise: With decades of experience, we understand the intricacies of beverage can manufacturing and deliver tailored solutions that enhance production.

- Precision-Driven Results: Designed to perform at high speeds without sacrificing quality.

- Global Reach: With knowledgeable sales and support representatives based in North America and Europe, we ensure responsive service and guidance for our customers worldwide.