Our partnership with you fosters close collaboration in developing precision tooling tailored to your needs. Our skilled craftsmen and engineers bring your designs to life, combining decades of expertise with cutting-edge technology to produce high-performance Food Can Tooling that meets the rigorous demands of modern production. Whether you need Two-Piece or Three-Piece Can Tooling, Bodymaker Punches, or Conversion Tooling, we ensure seamless integration into your manufacturing process. If you’re facing a challenge, our team is ready to collaborate and provide innovative solutions. When consistency and reliability are non-negotiable, Oberg delivers tooling that sets the industry standard.

Click on the specific Food Can Tooling below to learn more.

CAN TOOLING

Two Piece Can Tooling

Three Piece Can Tooling

Draw Redraw Tooling

Bodymaker Punches

Bodymaker Tooling

Scrap Choppers

Rotary Knives

SCROLL DIES

END TOOLING

Shell Tooling

Curler Tooling

End Tooling

Rivet & Tab Tooling

Double Dies

Carbide Score Tooling

Multi-Die Tooling

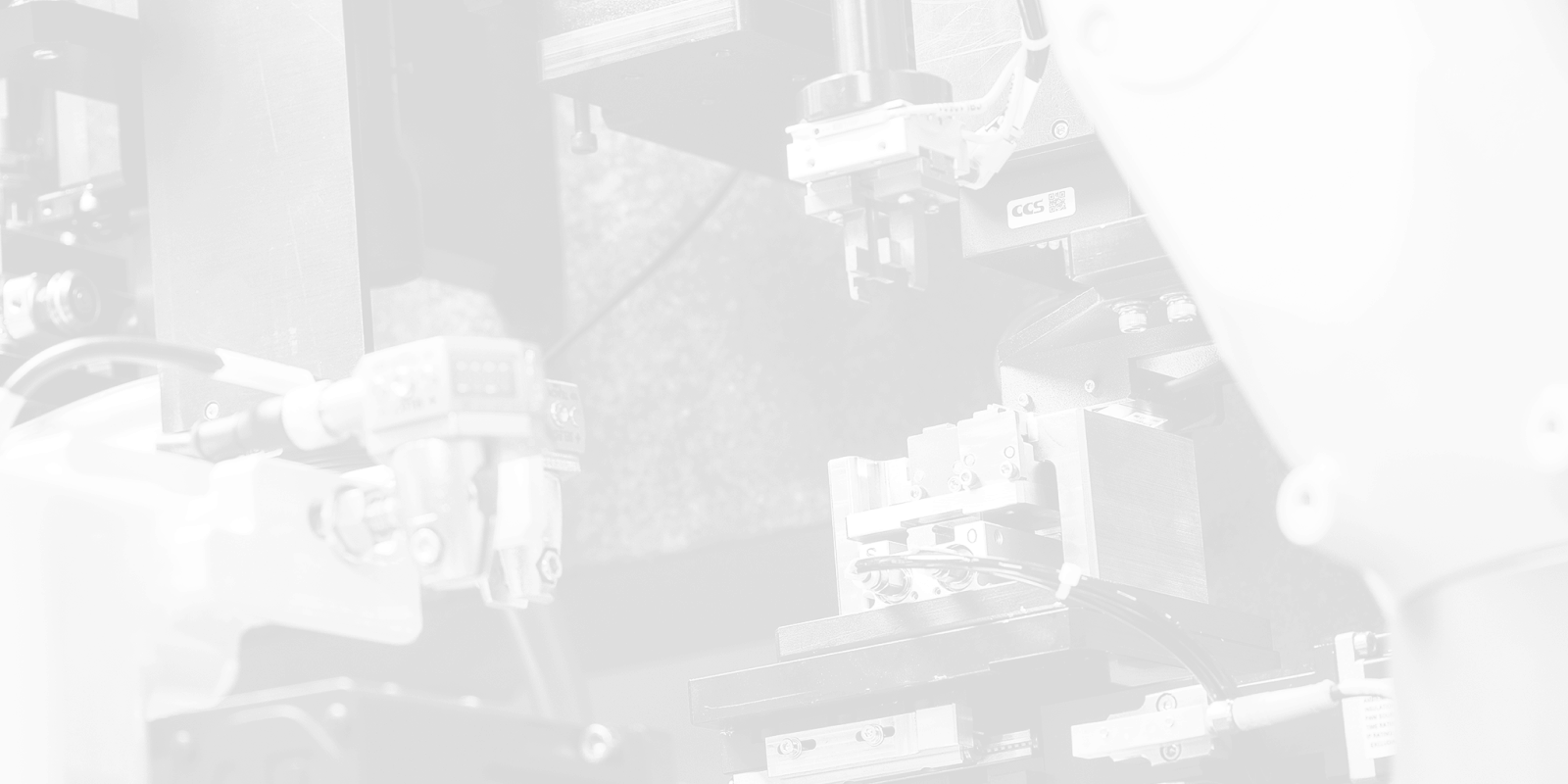

Machining/Turning/EDM

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

- Hard Turning Lathes

Precision Grinding

- Wave Shear Grinding

- Surface / Centerless

- Lapping / Polishing

- OD & ID (multi-axis grinding)

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide (Nickel, Cobalt)

- Alloy Steel (Stainless, Nickel, Tool Steel)

- Carbon Steel

- Ceramics

- Aluminum

- Powdered Tool Steels (CPM, M4, ASP)

Types of Food Can Tooling

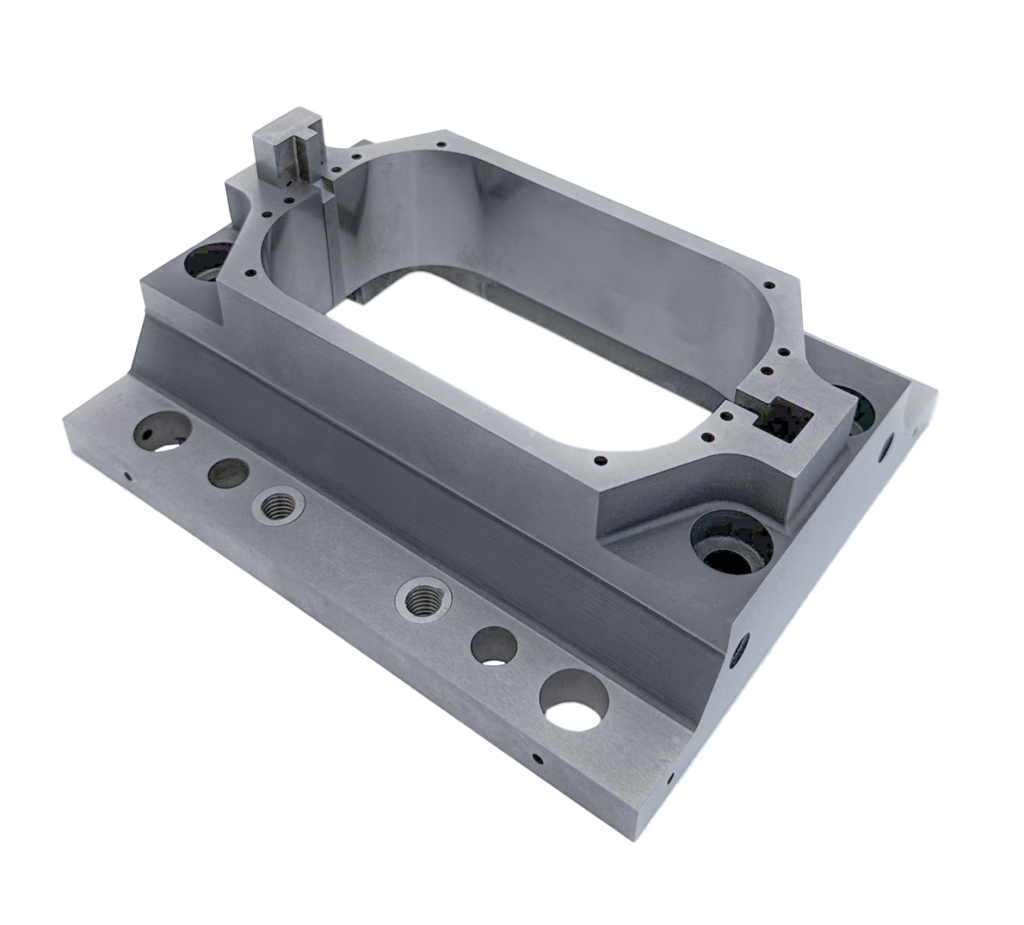

CAN BODY FORMING TOOLING

- Cupper Tooling: Starts the can-making process by blanking and drawing aluminum/steel sheets into uniform shallow cups, forming the foundation for accurate can shaping. Components include blank & draw dies, cupper punches, draw pads, and efficient scrap choppers to manage excess material.

- Body Maker Tooling: Transforms shallow cups into fully formed can bodies using redraw sleeves, ironing dies, and punches. This stage ensures precise wall thickness, dimensional accuracy, and the structural integrity needed for food containers.

- Beading Tooling: Adds structural reinforcement by creating beaded patterns on the can body, preventing paneling under pressure and maintaining can shape.

SHELL/END TOOLING

- Shell Tooling: Converts rolled flat aluminum/steel into circular blanks, or shells, which are then refined to form the end of the can. This tooling ensures uniform material distribution and prepares the shells for further processing.

- End Tooling: Develops fully functional can ends with features like easy-open tabs, rivets, and scoring. This tooling includes flanging and curling components to guarantee a secure fit and airtight seal.

- Seaming Tooling: Joins the can body and ends to form a reliable double seam. Our seaming tooling ensures the integrity of food containers, preventing leaks and preserving freshness.

CONVERSION TOOLING (RIVET AND TAB TOOLING)

- Rivet Tooling: Precisely forms rivets on can ends to secure pull tabs, ensuring reliability and consistent performance in opening mechanisms.

- Tab Tooling: Manufactures pull tabs with accuracy and strength, optimizing the opening experience while maintaining the integrity of the can end.

- Scoring and Curling Tools: Create score lines for easy tearing and curl the edges for a secure and smooth finish, ensuring the can end is easy to use yet durable enough to protect the contents.

Materials Engineered for Food Can Tooling

When it comes to food can production, the right tooling materials are critical for achieving reliable performance in a wide range of container shapes, sizes, and volumes. Oberg Industries delivers robust tooling solutions crafted from materials selected for their ability to meet the demands of high-speed food can manufacturing.

TUNGSTEN CARBIDE FOOD CAN TOOLING

Key Strengths: With unmatched wear resistance and durability, tungsten carbide tooling is ideal for handling the repetitive demands of high-output food can production.

Operational Benefits: These tools extend production uptime by reducing maintenance frequency and delivering consistent results, especially for applications requiring extreme durability.

TOOL STEEL FOOD CAN TOOLING

Versatility Across Applications: A wide variety of grades are available to meet the diverse requirements of cutting, forming, or shaping food cans.

Options for Every Demand:

- A2 Tool Steel: Exceptional toughness and versatility for standard forming and cutting tasks.

- D2 Tool Steel: High resistance to wear for intricate shaping and long production runs.

- S7 Tool Steel: Excellent for impact resistance in heavy-duty food can operations.

- H13 Tool Steel: Heat resistance makes it ideal for forming processes involving high temperatures.

- Powdered Tool Steels: Perfect for applications requiring long-term reliability and stress resistance.

CERAMIC FOOD CAN TOOLING

Advanced Durability: Offers unparalleled corrosion and heat resistance, making it ideal for precision-critical food can components.

Targeted Application: Best used in environments that demand dimensional stability at high temperatures.

Unique Challenges in Food Can Tooling

The diversity of food cans—ranging from round and standard designs to custom shapes for specialty applications—presents unique tooling challenges. Oberg ensures each solution is tailored to the needs of the food industry, with a focus on:

- Precision for Varying Dimensions: The ability to accommodate different sizes and shapes with accuracy.

- Reliable Material Compatibility: Ensuring tools are optimized for the steel and aluminum alloys commonly used in food can production.

- Performance at Scale: Balancing the requirements of high-speed, high-volume production with the need for durability and reliability.

What Sets Oberg Apart in Food Can Tooling?

When you partner with Oberg Industries for food can tooling, you benefit from solutions designed to support your operational success:

- Tailored Expertise: Decades of experience allow us to deliver custom tooling solutions for complex applications in food can manufacturing.

- Dependable Performance: Our tooling extends production cycles, reduces downtime, and ensures consistent results for even the most demanding operations.

- Collaborative Approach: We work closely with our customers to refine designs and create tools that enhance production efficiency and quality.