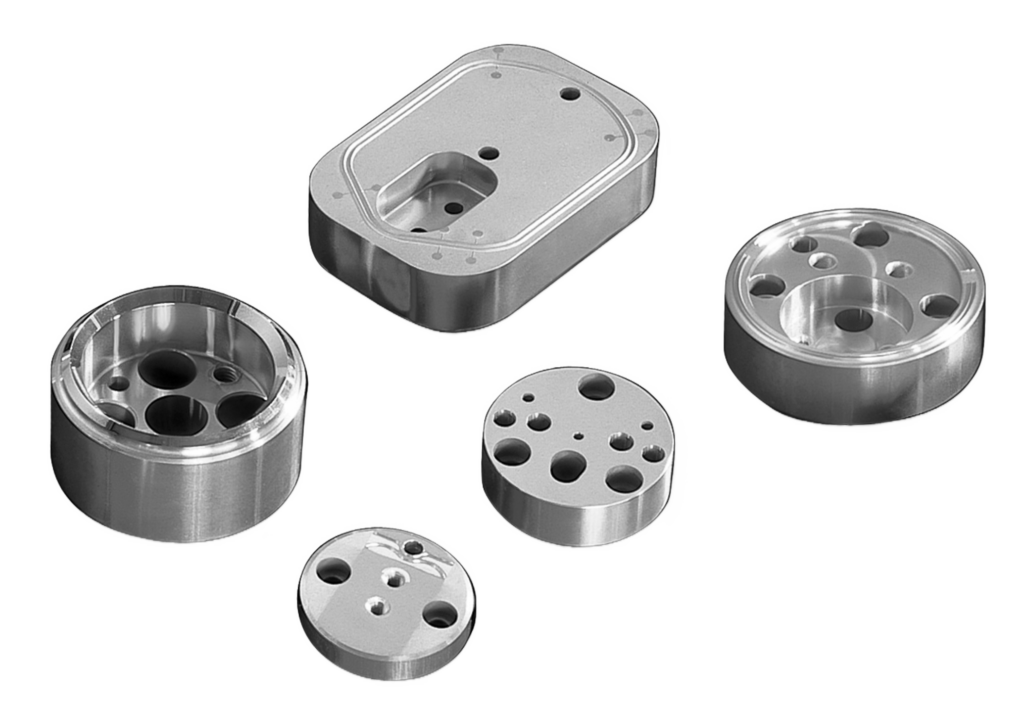

Oberg Industries is a leader in metal packaging tooling for the beverage, food, and specialty can industries. Our people and our passion make it happen. Our high-quality tungsten carbide, tool steel, and ceramic metal package tooling is custom-made, offering superior quality to resist damage and minimize maintenance for long-lasting performance on your product line.

Click on the specific metal packaging tooling below to learn more

CAN TOOLING

Two Piece Can Tooling

Three Piece Can Tooling

Aerosol Can Tooling

F-Style Can Tooling

Scrap Choppers

Rotary Knives

SCROLL DIES

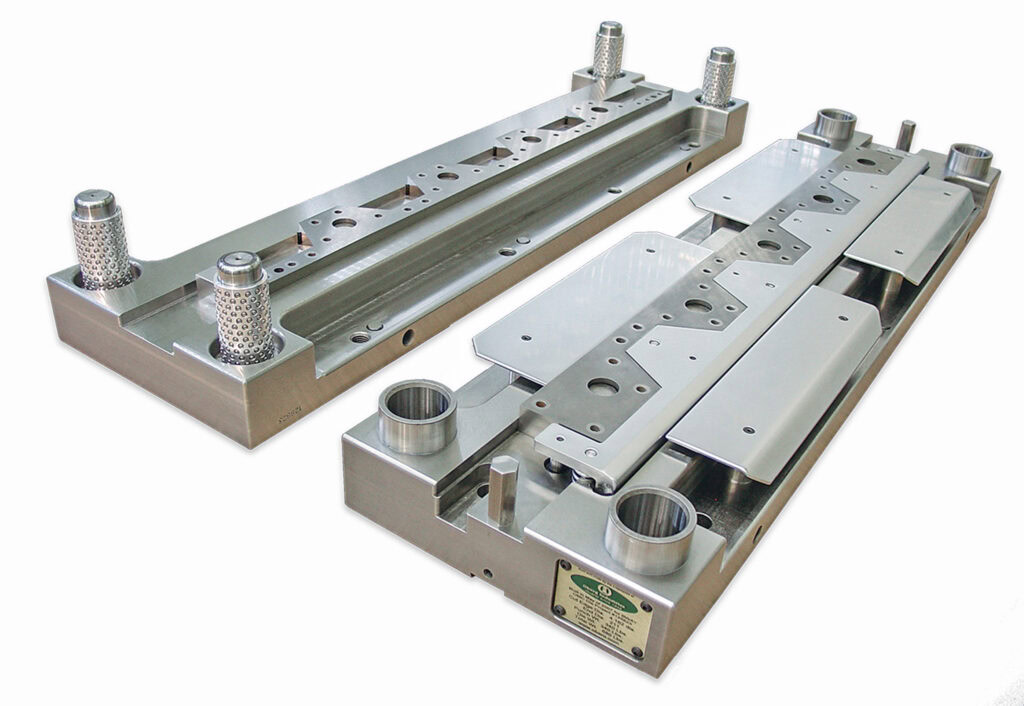

END TOOLING

Shell Tooling

Curler Tooling

End Tooling

Rivet & Tab Tooling

Double Dies

Carbide Score Tooling

Multi-Die Tooling

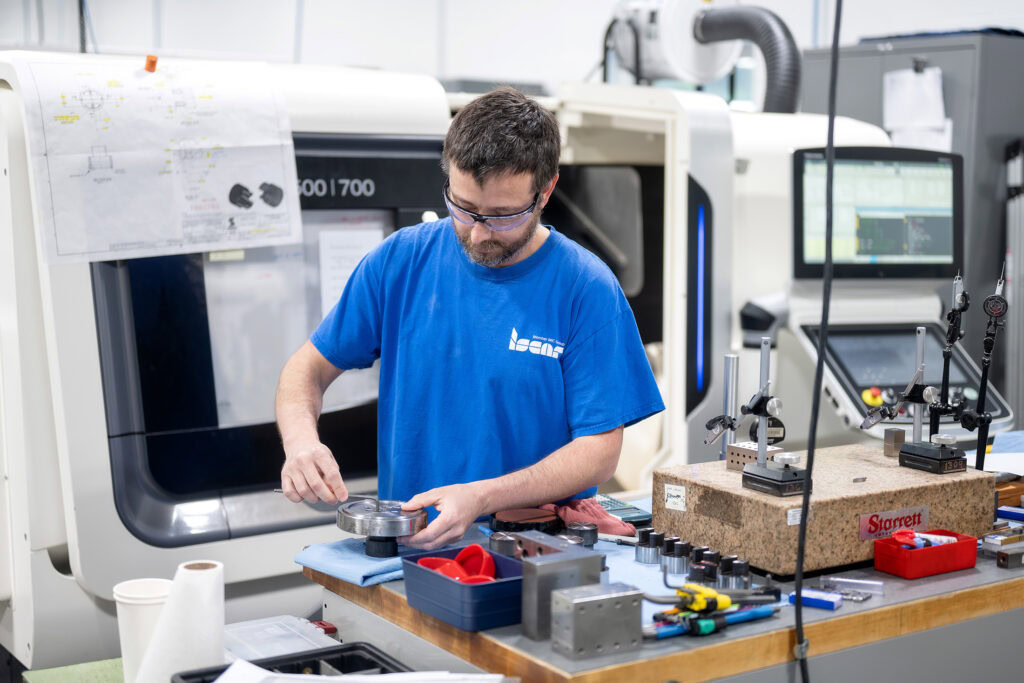

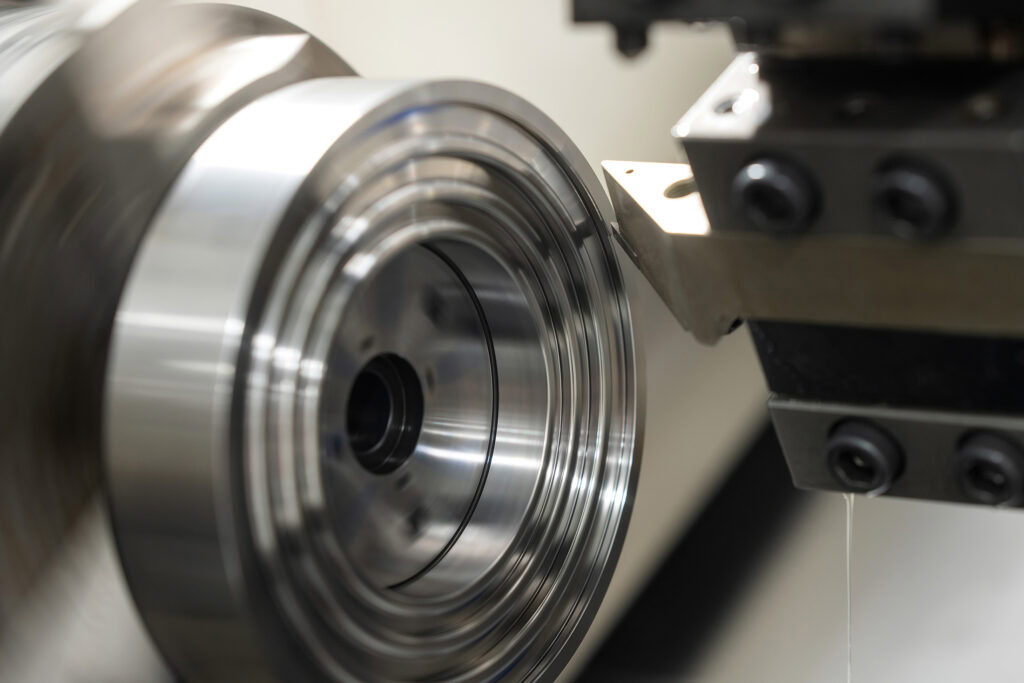

Machining/Turning/EDM

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

- Hard Turning Lathes

Precision Grinding

- Wave Shear Grinding

- Surface / Centerless

- Lapping / Polishing

- OD & ID (multi-axis grinding)

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide(Nickel, Cobalt)

- Alloy Steel (Stainless, Nickel, Tool Steel)

- Carbon Steel

- Ceramics

- Aluminum

- Powdered Tool Steels (CPM, M4, ASP)

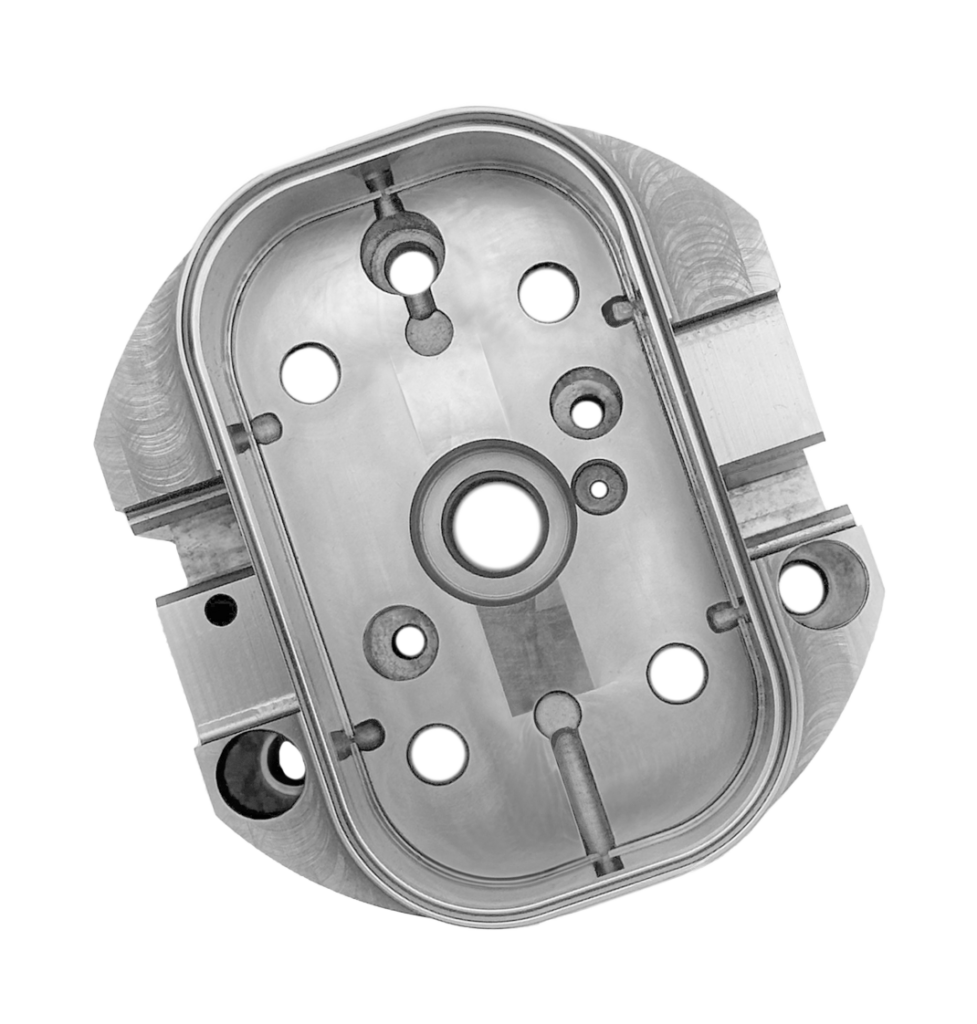

Types of Specialty Can Tooling

Specialty can tooling often require a customized approach, incorporating similar components used in food and beverage can manufacturing but with tailored specifications for unique shapes and applications. Our tooling solutions ensure that even the most unconventional designs—such as Aerosol Cans, F-style cans, holiday tins, and gas cans—are produced with precision, durability, and quality.

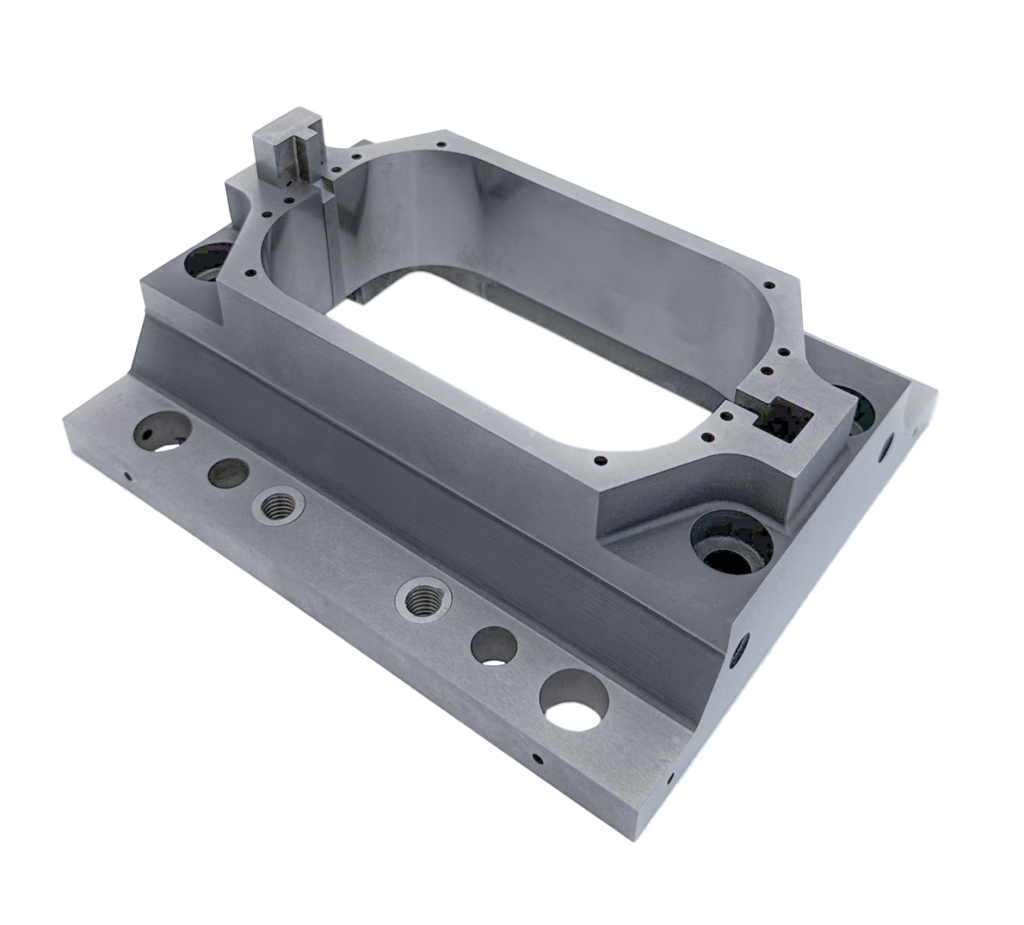

CUSTOM CAN BODY TOOLING

Non-Round Can Tooling: We specialize in tooling for non-round shapes, such as rectangular, oval, or custom contours. Our solutions ensure precise forming, consistent wall thickness, and structural integrity, even for complex geometries.

Aerosol Can Tooling: Our aerosol can tooling supports precise forming and consistent shaping to meet high-speed production demands. Built for reliability, these tools ensure uniform structure and integrity for pressurized container applications.

F-Style Can Tooling: Whether rectangular or oblong, our F-style tooling supports efficient manufacturing and space-saving designs. These cans, often used for industrial chemicals, paints, automotive fluids, and household products, require precise tooling to achieve their flat-bottomed, durable structure and secure closures.

Slim and Tall Can Tooling: Our tooling for slim and tall cans is crafted to maintain stability and uniformity, reducing material waste and optimizing production speed. With advanced materials, such as tungsten carbide, we enhance tool life and minimize maintenance.

Beading Tooling: Adds structural reinforcements to specialty and Aerosol cans, preventing deformation and enhancing durability for containers used in demanding applications.

END TOOLING FOR AEROSOL CANS AND SPECIALTY CANS

Custom Shell Tooling: Supports the unique shell designs that align with various specialty can shapes, ensuring reliable material distribution and dimensional stability.

Specialty End Features: We offer Tooling for easy-open ends, rivet tabs, and custom scoring patterns tailored to your design specifications for perfect fit and functionality.

Seaming Tooling: Joins can bodies and ends with high precision, using techniques adapted for specialty and Aerosol applications to ensure airtight and reliable seals.

Note: While these tooling types may resemble those used in traditional can manufacturing, they are meticulously engineered to meet the unique specifications of Specialty and Aerosol can designs. At Oberg, we aim for manufacturability to meet the demands of your project and designs, regardless of complexity.

Materials Used in Aerosol Can Tooling and Specialty Can Tooling

We select high-quality materials to meet the demands of Aerosol and specialty can manufacturing, each chosen for its performance in high-stress and complex environments.

TUNGSTEN CARBIDE SPECIALTY CAN TOOLING

Durability: Exceptional wear resistance, ideal for non-round and high-volume applications.

Cost Efficiency: Despite a higher initial investment, tungsten carbide reduces long-term costs by minimizing maintenance and maximizing tool life.

TOOL STEEL SPECIALTY CAN TOOLING

Versatility: Available in multiple grades to suit various forming, cutting, and shaping tasks.

Tool Steel Grades:

A2 Tool Steel: Balances toughness and wear resistance for general-purpose use.

D2 Tool Steel: Offers high wear resistance, perfect for forming and cutting applications.

S7 Tool Steel: Known for impact resistance and toughness.

H13 Tool Steel: Heat resistant, ideal for hot work processes.

Powdered Tool Steels: Offers exceptional wear resistance and longevity for high-stress applications, providing versatility at a lower cost than tungsten carbide.

CERAMIC SPECIALTY CAN TOOLING

Precision and Stability: Handles extreme heat and corrosion, ensuring consistent results in specialized environments.

Application: Best suited for intricate, heat-resistant components where precision is critical.

The Oberg Advantage for Aerosol Can Tooling and Specialty Can Tooling

Innovative Design Capabilities: Our engineering team excels in creating custom tooling solutions tailored to your exact specifications, ensuring your cans stand out in the market.

Unmatched Precision: Using advanced manufacturing techniques, we guarantee dimensional accuracy and high performance for every unique can shape.

Long-Lasting Durability: Our tooling is crafted from top-grade materials to extend tool life, minimize downtime, and lower overall production costs.

Collaborative Approach: We work closely with your team from design to production, ensuring our solutions align perfectly with your goals and manufacturing processes.