Oberg’s Two-Piece Can Tooling Solutions Include:

- Cupper Tooling: Shapes flat metal sheets into the initial cups, establishing a uniform base for further can formation. This tooling ensures exactness from the start, critical for a smooth production flow.

- Draw/Redraw Tooling: Gradually reshapes metal cups into taller, uniform containers while maintaining precise wall thickness and structural integrity.

- Shell Tooling: Shapes and prepares the top end of the can for precise rolling and seaming. Our tooling ensures an airtight closure, which is essential for product safety and freshness.

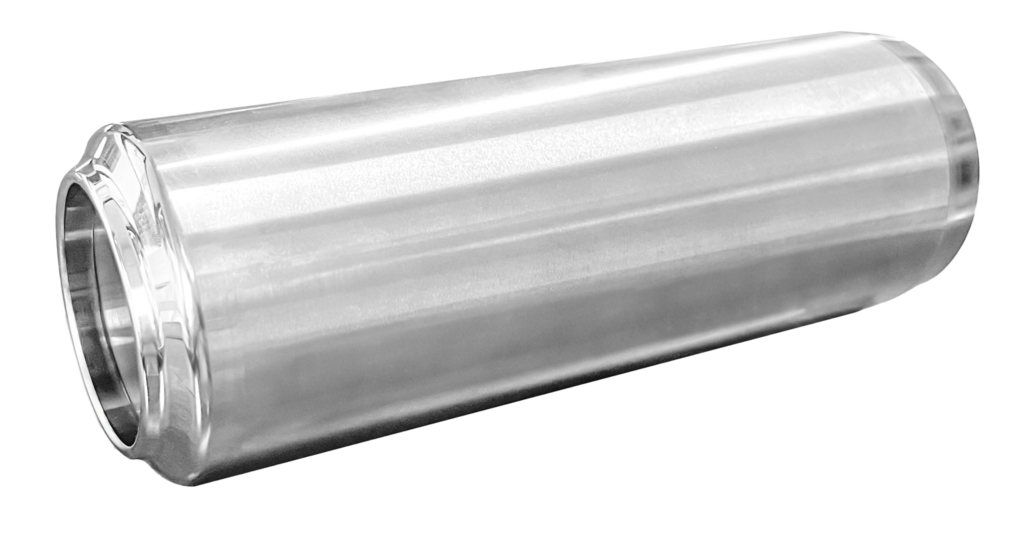

- Bodymaker Tooling: Transforms the cups into their final cylindrical form, maintaining wall thickness and a polished surface. Oberg’s expertly engineered tools support efficient, high-speed operations without sacrificing quality.

- Necker Tooling: Reduces the diameter at the open end of the can, preparing it for end attachment. Our precision necking tools provide a secure fit while optimizing material usage for cost-effectiveness.

- Trimming and Flanging Tools: Trim cans to a uniform height and shape the edges to prepare for seaming. Oberg’s flanging solutions ensure the can is ready for secure sealing, contributing to leak-free performance.

Advantages of Oberg’s Two-Piece Can Tooling:

- Efficient Production: Our tooling is designed to integrate seamlessly into high-speed manufacturing lines, boosting productivity and minimizing disruptions.

- Material Efficiency: Engineered to minimize waste, our solutions help you maximize resource use without compromising can durability.

- Long-Lasting Performance: Using robust materials like tungsten carbide and ceramics, our tooling delivers extended service life, reducing the need for frequent maintenance.

Oberg Industries combines innovation and craftsmanship to deliver tooling solutions that elevate your two-piece can manufacturing. From cup formation to precise end seaming, our tools are crafted to support consistent, top-tier production standards.

Learn More About Our Two-Piece Can Tooling Solutions.