Key Bodymaker Tooling Components by Oberg Industries:

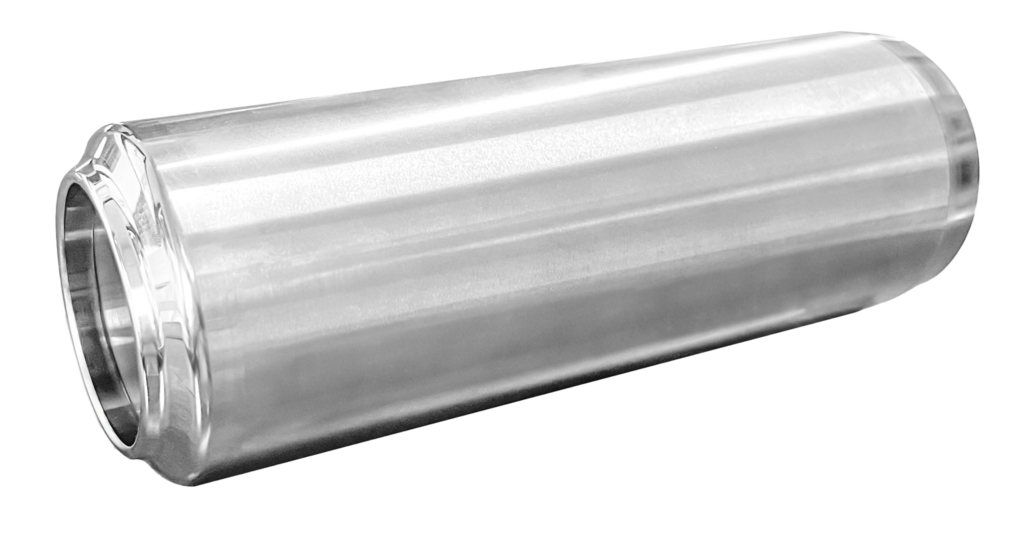

REDRAW SLEEVES

- Function: Redraw sleeves support the can body through multiple forming stages, refining its shape and ensuring uniform wall thickness. These sleeves minimize material stress, prevent defects, and enhance production efficiency, delivering consistent, high-quality results in high-speed can manufacturing.

DOMER TOOLING

- Function: Domer tooling forms the can body’s dome, creating the precise contour needed for structural integrity and pressure resistance. This tooling ensures a smooth transition through forming stages, optimizing material flow and maintaining the dimensional accuracy required for seamless production.

DRAWING DIES

- Function: These dies shape the blank into a cup, reducing its diameter while increasing its depth. Our drawing dies are engineered to withstand high pressures and deliver precise results critical for the accuracy and uniformity of each can body.

IRONING DIES

- Function: Ironing dies thin the walls of the drawn cup to the desired thickness while maintaining the cup’s shape and structural integrity. This step is essential for achieving uniform wall thickness and strength, ensuring the final can body meets rigorous quality standards.

TRIMMING KNIVES

- Function: After the drawing and ironing process, trimming knives remove excess material from the can body. These knives ensure a clean, consistent finish, enhancing the quality and consistency of each can produced.

Body Maker Tooling Engineered for Durability and Precision

Each component in our Bodymaker Tooling suite is crafted from high-performance materials like tungsten carbide and tool steels, known for their wear resistance and long service life. Our tooling solutions are tailored to meet the demands of modern can production, empowering manufacturers to efficiently and consistently produce high-quality, structurally sound cans.

Enhance Your Production Line with Oberg’s Tooling Expertise.

From the initial blanking to the final shaping, Oberg Industries delivers high-performance bodymaker tooling that keeps your production line running smoothly and delivers quality in every can. Trust our expertise to support your manufacturing goals with precision and reliability.

Contact Us to Learn More About Our Bodymaker Tooling Solutions.