What Are Electrical Terminals?

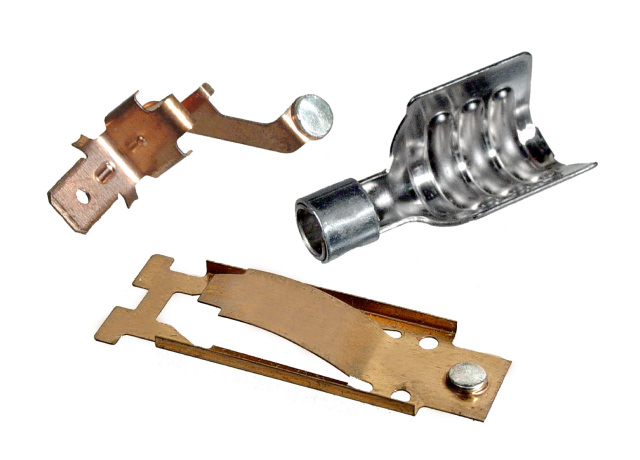

Electrical terminals play a crucial role in power generation, industrial equipment, and renewable energy systems, providing a secure interface between wires and power components such as motors, generators, and transformers. Manufactured to customer specifications, Oberg Industries produces high-precision electrical terminals to support efficient current flow and system reliability in demanding applications.

Precision-Manufactured for Critical Power Applications

Oberg manufactures electrical terminals with a focus on material consistency, conductivity, and tight tolerances. Every component is produced using precision machining and stamping processes to meet the exact requirements of power generation systems.

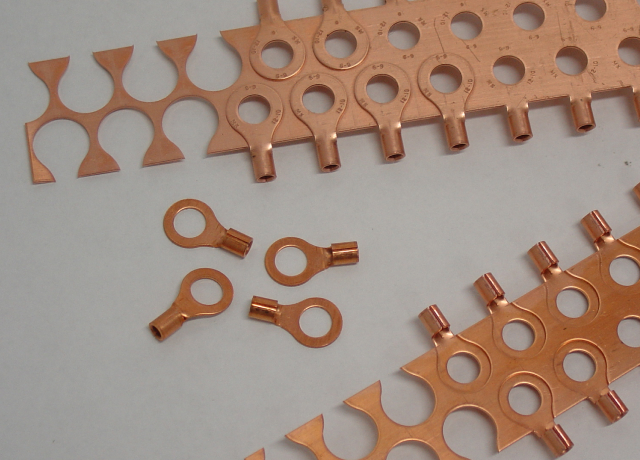

- Material Expertise: Using copper, aluminum, and other conductive materials to ensure high performance.

- Precision Manufacturing: Ensuring tight tolerances for secure and reliable connections.

- Custom Solutions: Designed to meet the exact needs of your system.

Applications in Energy and Industrial Systems

Oberg provides electrical terminal manufacturing solutions for a variety of industries, including:

-

- Renewable energy systems such as solar arrays and wind turbines

- Industrial motors used in manufacturing and automation

- Power plants and large-scale energy distribution systems

Manufactured for Performance and Durability

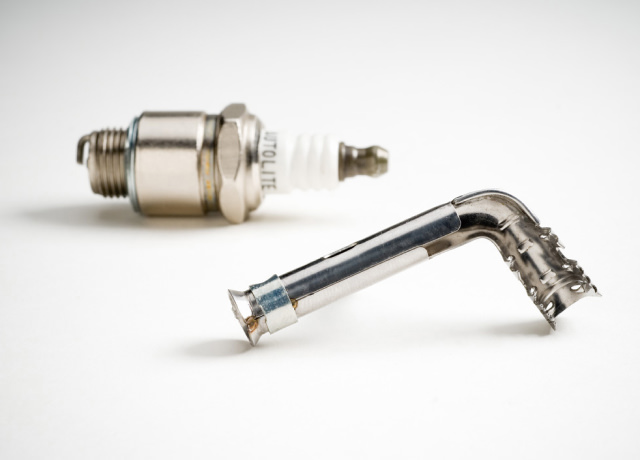

Electrical terminals are subjected to extreme conditions, including heat, vibration, and heavy electrical loads. It’s critical that Oberg’s manufacturing meets your design parameters exactly. Our expertise ensures this so that each terminal is built for long-term reliability, with materials and processes tailored to meet the most rigorous industry requirements.

Custom Electrical Terminal Solutions to Meet Your Needs

Oberg Industries manufactures electrical terminals to customer specifications, supporting power generation and industrial energy applications.

Contact us today to discuss how precision manufacturing can help meet your electrical terminal requirements.