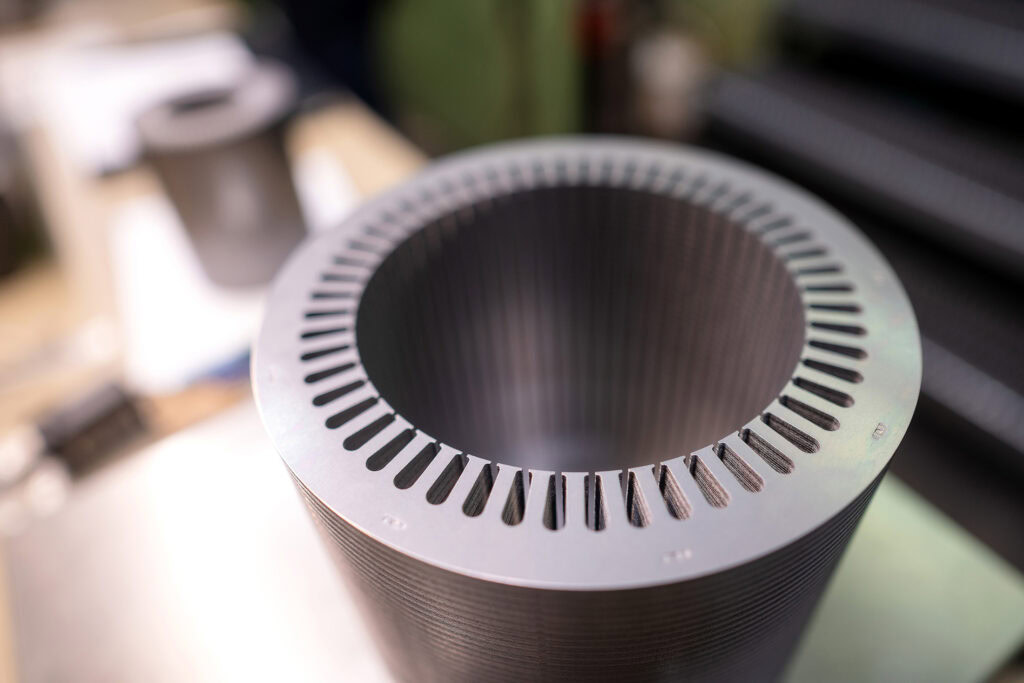

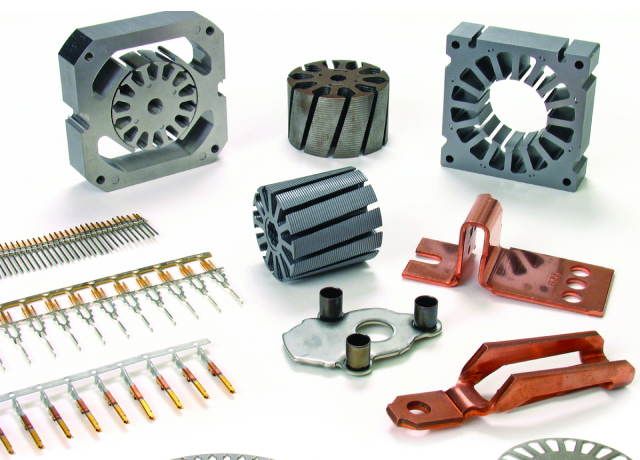

What Are Motor and Generator Laminations?

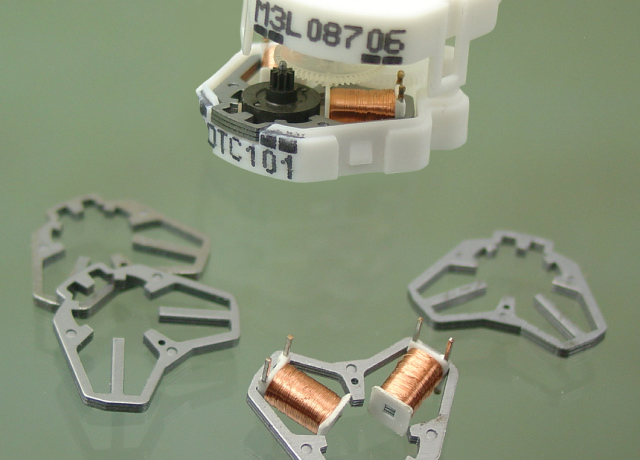

Motor and generator laminations are thin sheets of magnetic steel, stacked or bonded together to form the core of electric machines. Manufactured to customer-supplied designs, these laminations help reduce energy losses caused by eddy currents and heat, supporting efficient operation in motors, generators, and transformers.

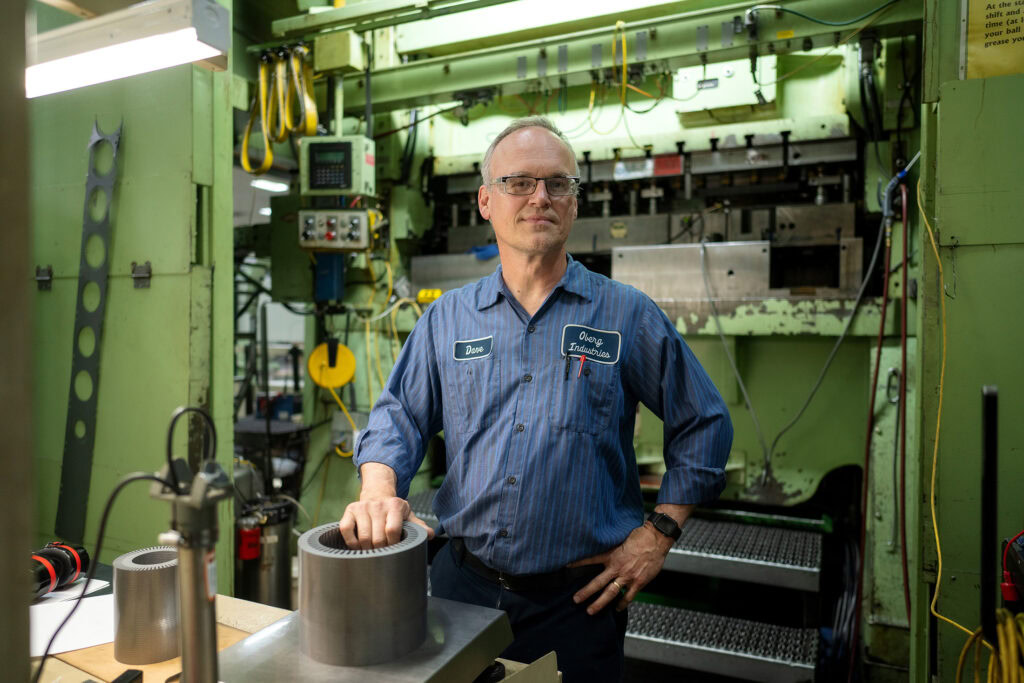

Why Choose Oberg for Motor 0r Generator Laminations?

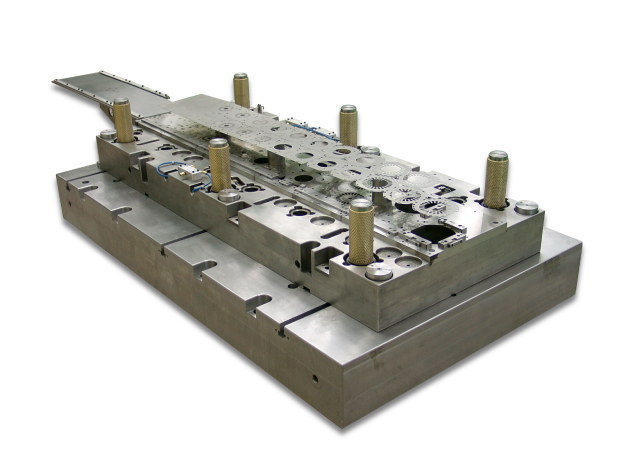

- High-Precision Stamping – Manufactured with tight tolerances for repeatable, high-quality performance.

- Material Expertise – Processed using customer-specified magnetic steels to meet efficiency and durability requirements.

- Custom Tooling & Manufacturing – In-house die-making and stamping capabilities ensure laminations are produced to exact specifications.

Applications in Power Generation

Oberg manufactures laminations for a variety of power generation and energy applications, including:

-

- Electric Motors – Used in wind turbines, industrial equipment, and EV propulsion systems.

- Generators – Supporting renewable and conventional power systems.

- Transformers – Manufactured to print. So they optimize power distribution and energy efficiency.

PRECISION MANUFACTURING FOR ENERGY EFFICIENCY

Oberg Industries manufactures customer-specified motor and generator laminations with a focus on precision stamping and material consistency.

Contact us today to learn more about our motor lamination and generator lamination solutions.