- Electric and hybrid vehicle motor laminations

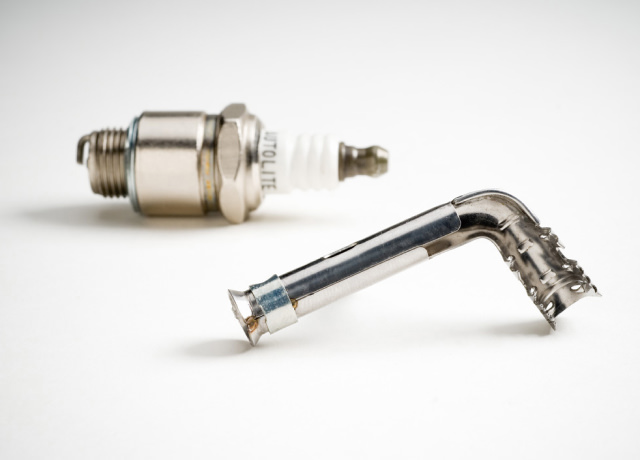

- Electrical connectors and terminals

- Bus bar

- Tooling for thin film battery applications

- Progressive stamping dies

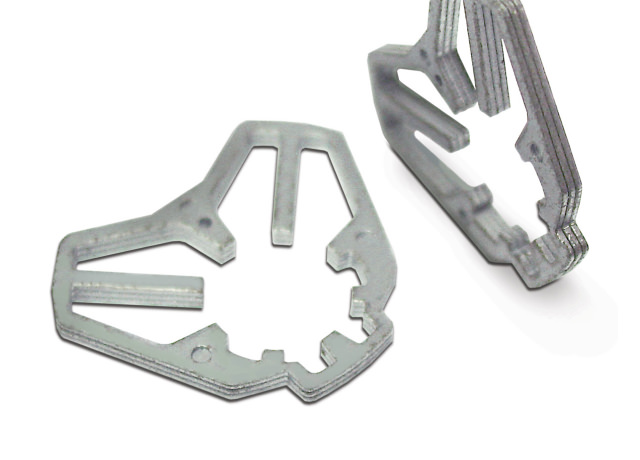

- Stamped parts

- Assembly systems and precision assemblies

POWER GENERATION

Motor & Generator Laminations

Electrical Terminals

Bus Bars

BATTERIES

Film Cutting Tooling

Anode & Cathode End Cap Tooling

Case Draw Tooling

Design for Manufacturing and Design for Assembly (DFM/DFA)

Prototyping Services

Tooling & Stamping

- In-house engineering design (progressive dies, fixtures)

- 50+ presses from 5 to 400 tons

- Hydraulic and Mechanical Presses

- Assembly and value added processes

- Tooling Rework Programs

Machining/Turning/EDM

- Multi-Axis Milling – 3/4/5-axis

- Turning

- Hard Turning Lathes

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn (Chicago plant)

Precision Grinding

- Surface / Centerless

- OD & ID (multi-axis grinding)

- Lapping / Polishing

Special / Secondary Processes

- Heat Treating – vacuum heat treating and heat treating ovens

- Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- CMM Inspection

- Validated Special Processes

- Vision Systems

Assembly Cells

- Full automation

- Kitting, Packaging, Labeling

- Stainless Steel

- Tungsten Carbide

- Copper

- Brass

- Bronze

- Titanium

- Aluminum

- Thermoplastics