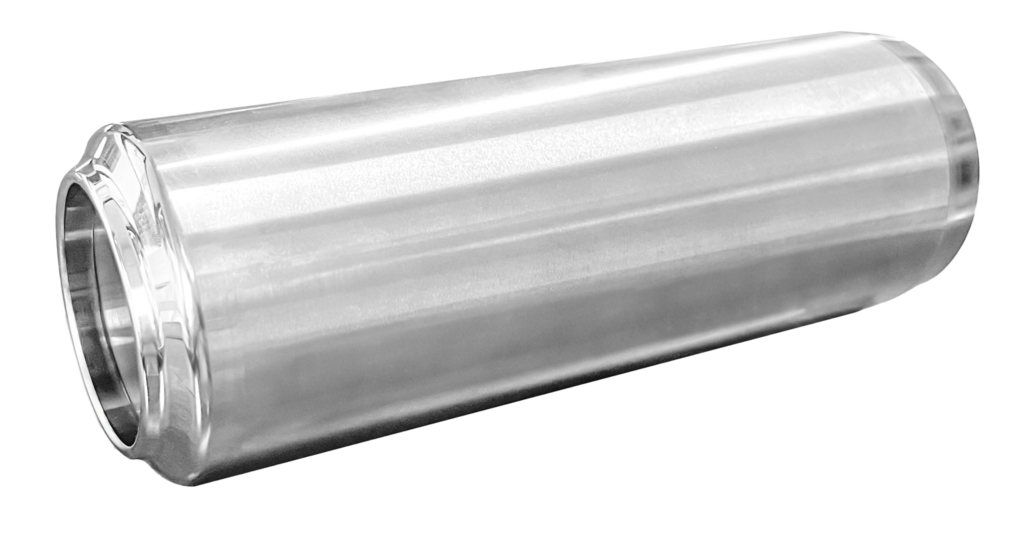

Boost Your Production Line with Oberg’s Bodymaker Punches:

With Oberg’s bodymaker punches, you’ll experience reliable performance, reduced downtime, and seamless integration into your existing systems

WHY OBERG BODYMAKER PUNCHES STAND OUT:

- Precision Engineering: Our bodymaker punches are crafted to exact specifications for consistent, high-quality can formation.

- Unmatched Durability: Built from advanced materials like Tungsten Carbide, Tool Steels, and Ceramics, our punches are made to last through high-volume production.

- Custom Solutions: Tailored to your unique production needs, maximizing efficiency and reducing waste.

Enhance Your Can Production with Confidence

Trust Oberg to deliver can tooling that keeps your production running at peak performance.

Let’s redefine what’s possible in metal packaging.

Learn More about our Bodymaker Punches.