Oberg Industries is a leader in metal packaging tooling for the beverage, food, and specialty can industries. Our people and our passion make it happen. Our high-quality tungsten carbide, tool steel, and ceramic metal package tooling is custom-made to the customer print, design and specifications. Offering superior quality to resist damage and minimize maintenance for long-lasting performance on your product line.

METAL PACKAGING TOOLING

Click on the specific metal packaging tooling below to learn more.

Beverage Can Tooling

Body Maker Punches

Body Maker Tooling

Can Tooling

Conversion Tooling

Cupper Tooling

Cupper Wear Components

Curler Tooling

Double Dies

Draw Redraw Tooling

End Tooling

Food Can Tooling

Necker Tooling

Non-Round Can Tooling

Rivet & Tab Tooling

Rotary Knives

Score Tooling

Scrap Choppers

Scroll Dies

Shell Tooling

Specialty Can Tooling

Three Piece Can Tooling

Two Piece Can Tooling

Machining/Turning/EDM

Over 90 machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

Precision Grinding

Over 200 machines

- Wave Shear Grinding

- Surface / Centerless

- Jig / Advanced MDP®

- Lapping

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

- 50+ presses from 5 to 400 tons

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide

- Stainless Steel

- Tool Steels

- Ceramics

Types of Can Tooling

Beverage Can Tooling

Our high-quality beverage can tooling includes solutions for both two-piece and three-piece cans, designed for precision and durability. We optimize every component to ensure efficient, high-speed production with minimal waste. Learn more

Food Can Tooling

Oberg’s food can tooling accommodates various shapes and sizes, providing strength and reliability for all your metal food packaging needs, from durable bodies to easy-open ends. Learn more

Specialty Can Tooling

We offer custom specialty can tooling for unique applications, such as non-round cans, holiday tins, gas cans, and various container lids. Our innovative solutions ensure reliable performance for even the most complex designs. Learn More

Types of Can Tooling Materials

Tungsten Carbide Can Tooling– Superior strength, wear resistance, and durability make tungsten carbide tooling ideal and preferred for food can-making.

Tool Steel Can Tooling – Excellent machinability and formability with a wide range of tool steel grades, depending on the application.

Ceramic Can Tooling – Corrosion resistant with superior wear resistance, creating a longer tool life in harsh environments.

Can Tooling Components

CAN BODY FORMING TOOLING

- Cupper Tooling: Begins the can-making process by blanking and drawing metal sheets into uniform shallow cups, setting the stage for accurate shaping. This step includes blank & draw dies, cupper punches, draw pads, and efficient scrap choppers for material management.

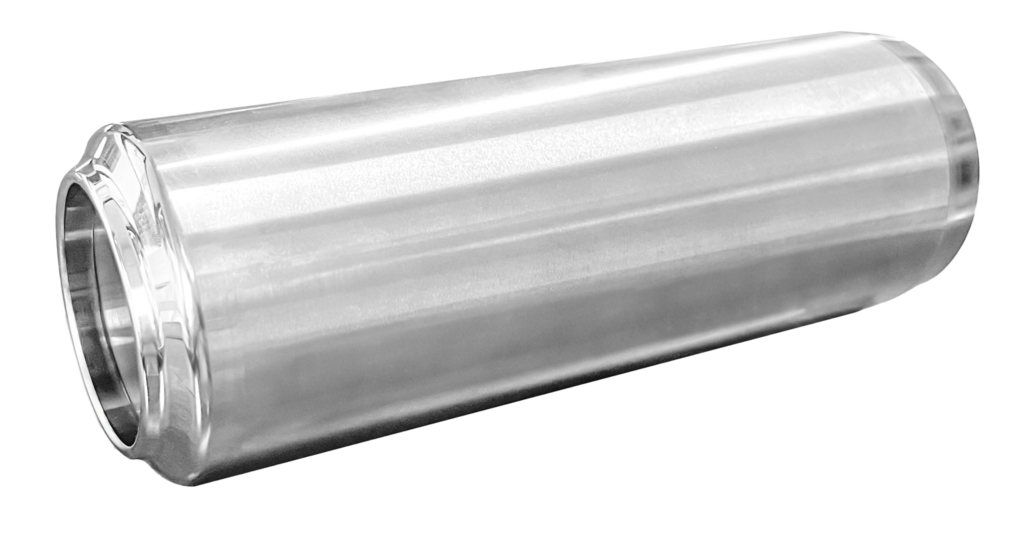

- Body Maker Tooling: Extends shallow cups into robust, cylindrical can bodies with consistent wall thickness. Using re-draw sleeves, ironing dies, and punches, this tooling ensures dimensional precision and durability, essential for both food and beverage cans.

- Beading Tooling: Reinforces can bodies by adding bead patterns, preventing deformation under internal or external pressure, which is especially vital for food and pressurized beverage cans.

- Necker Tooling: Forms a precise neck on the can body to match the lid’s specifications, using dies, spin rollers, and curl/flange tools. This tooling ensures a secure fit for lids and maintains uniform performance across production.

SHELL/END TOOLING

- Shell Tooling: Converts flat sheets into circular shells, serving as the foundation for can ends. This process ensures uniform material distribution and prepares the shells for further refinement.

- End Tooling: Develops complete can ends with features like easy-open tabs, rivets, and scoring. Flanging and curling components guarantee a secure fit and airtight seal, maintaining product integrity and safety.

- Seaming Tooling: Joins the can body and ends by forming a tight, leak-proof double seam. This tooling is critical to preserving contents and preventing contamination or leakage.

- Curler Tooling:Shapes the edges of can components, curling them to create a smooth, rounded finish. This process prepares the edges for effective seaming, ensuring a secure and safe connection.

CONVERSION TOOLING (RIVET AND TAB TOOLING):

- Rivet Tooling: Forms rivets on can ends with precision, ensuring pull tabs are securely attached for dependable, easy-open functionality.

- Tab Tooling: Produces strong, accurately placed pull tabs to facilitate easy opening while protecting the can’s integrity.

- Scoring and Curling Tools: Creates score lines for effortless tearing and curls the edges to form a smooth, secure finish, balancing ease of use with durability.

Note: While not every can product requires all these tooling types, Oberg Industries offers the flexibility and expertise to provide tailored solutions for your specific needs, ensuring optimal performance and efficiency.

Can Tooling Tidbits

What is the difference between two-piece can tooling and three-piece can tooling?

Two-piece can tooling creates cans with a body and a single end, joined together during the manufacturing process. These cans are often used for beverages because the seamless body is stronger, making it better for carbonated drinks. The two-piece design also reduces material waste and improves production speed.

Three-piece can tooling, on the other hand, forms the can by creating a body and two separate ends, which are then joined together. This design is more flexible for different shapes and sizes of cans and is often used for food packaging. Three-piece cans are generally preferred for their ability to handle a wider range of can heights and diameters, making them ideal for products like soups, sauces, and other preserved foods.

Why choose two-piece or three-piece can tooling?

Two-piece cans are generally lighter and stronger, making them ideal for high-volume production of beverage cans, especially those holding carbonated drinks. Three-piece cans, while slightly more complex to manufacture, offer greater versatility in terms of size and shape, making them the go-to choice for more specialized applications like food cans.

What is the difference between End and Shell Tooling?

Shell tooling forms flat metal sheets into circular shells, laying the foundation for can ends. End tooling then transforms these shells into functional can ends, adding features like pull tabs, rivets, and scoring for easy opening while ensuring a secure, airtight seal.

Why is Cupping Essential for Can Integrity?

The birthplace of a can…High-quality cupper tooling is fundamental to starting the can-making process correctly. A perfectly formed cup ensures that all subsequent stages operate smoothly and efficiently. By maintaining precise dimensions from the beginning, cupper tooling promotes product uniformity, reducing the risk of defects as the cup transforms into the final container.

Elevate your can production, efficiency, and quality. Contact Oberg Industries today to learn how our expertise in can tooling can drive your success.