Oberg Industries is a leader in metal packaging tooling for the beverage, food, and specialty can industries. Our people and our passion make it happen. Our high-quality tungsten carbide, tool steel, and ceramic metal package tooling is custom-made, offering superior quality to resist damage and minimize maintenance for long-lasting performance on your product line.

METAL PACKAGING TOOLING

Click on the specific metal packaging tooling below to learn more.

Beverage Can Tooling

Body Maker Punches

Body Maker Tooling

Can Tooling

Conversion Tooling

Cupper Tooling

Cupper Wear Components

Curler Tooling

Double Dies

Draw Redraw Tooling

End Tooling

Food Can Tooling

Necker Tooling

Non-Round Can Tooling

Rivet & Tab Tooling

Rotary Knives

Score Tooling

Scrap Choppers

Scroll Dies

Shell Tooling

Specialty Can Tooling

Three Piece Can Tooling

Two Piece Can Tooling

Machining/Turning/EDM

Over 90 machines

- Multi-Axis Milling

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn

Precision Grinding

Over 200 machines

- Wave Shear Grinding

- Surface / Centerless

- Jig / Advanced MDP®

- Lapping

Tooling + Stamping

- Carbide Primary and Secondary Scroll Dies

- Tooling Rework Programs

- 50+ presses from 5 to 400 tons

Special / Secondary Processes

- Heat Treating + Cryogenics

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- Tungsten Carbide

- Stainless Steel

- Tool Steels

- Ceramics

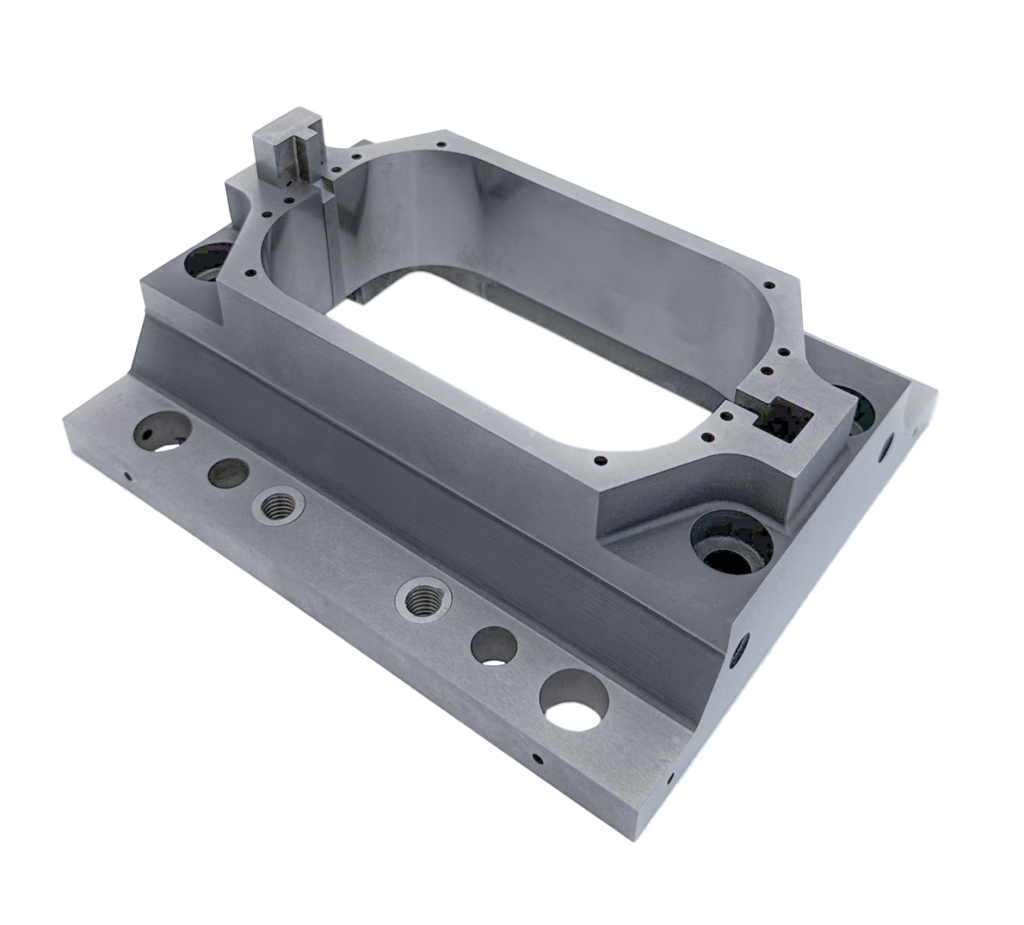

Our Non-Round Can Tooling Arsenal:

- Non-Round Custom Cupper Tooling: Think outside the circle! Our tools expertly shape flat metal sheets into non-round cups with uniform material distribution, setting the stage for flawless can-bodies.

- Non-Round Forming Tooling: We’ve got you covered, whether you’re looking for a quirky curve or a sleek, straight edge. Our forming tooling ensure your cans have consistent wall thickness and the resilience to withstand the rigors of production.

- Non-Round Necking and Flanging Tools: These aren’t your standard tools; they’re meticulously crafted to handle the unique contours of non-round cans, guaranteeing a snug, secure fit for end components.

- Non-Round Shell/End Tooling: Do you need ends that perfectly seal your out-of-the-box can shape? We engineer tooling to create can ends that align seamlessly with your vision, preserving product integrity and freshness.

Why Oberg for Non-Round Can Tooling?

- Boundary-Pushing Expertise: Our engineers thrive on the challenge of creating tooling for unconventional shapes, making even the most complex designs a reality.

- Durability You Can Depend On: Built with high-performance materials like tungsten carbide, our Non-Round Can Tooling withstands the demands of high-speed, high-volume production.

- Tailor-Made Precision: Every tool is a bespoke creation, fine-tuned to meet your unique specifications and maximize efficiency on your production line.

Ready to Transform Your Packaging with Oberg’s Non-Round Can Tooling?

It’s time to make your packaging unforgettable. From sketch to shelf, Oberg Industries is here to turn your boldest can concepts into high-quality, production-ready containers from sketch to shelf. Discover the possibilities within our Specialty Can Tooling line.

Let’s talk about our Non-Round Can Tooling solutions.