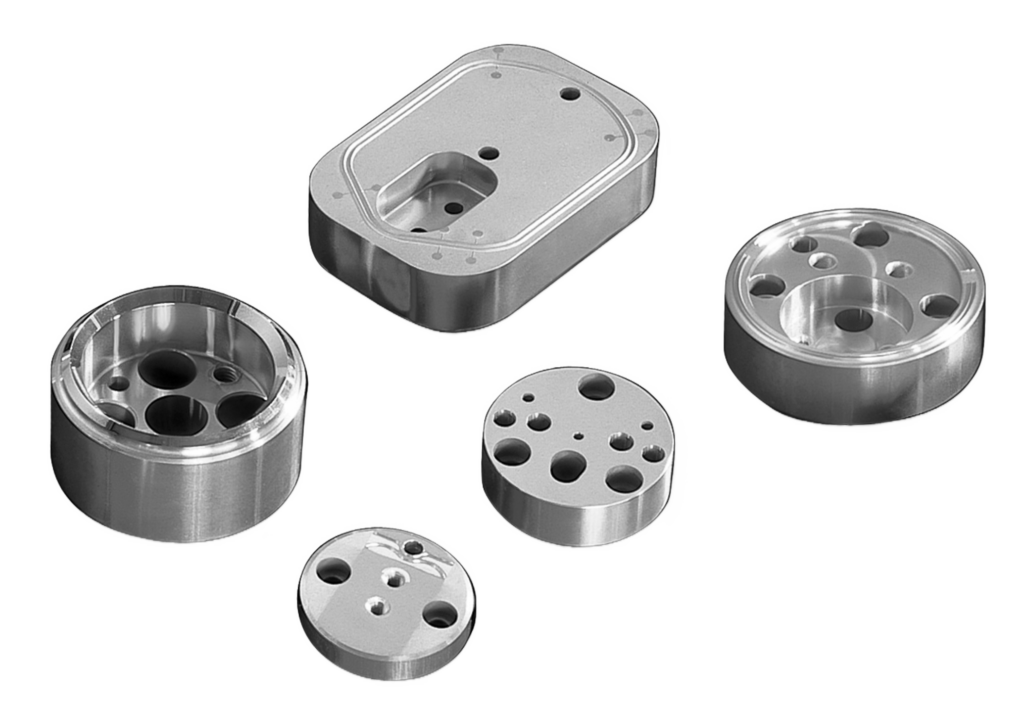

Key Aspects of Oberg’s Score Tooling

- Precision Scoring Dies

Our scoring dies produce finely controlled score lines that enable easy-opening without weakening the overall can structure. Each die is crafted to create smooth, uniform scores for an optimal consumer experience. - High-Strength Design for Continuous Production

Oberg’s score tooling is engineered from durable materials like tungsten carbide and tool steels to enable high-speed production environments, maintain reliable performance, and reduce wear. - Uniform Scoring Consistency

Every tool is designed for consistent score depths and strength, ensuring reliable, repeatable results across production runs.

Delivering Reliable, Easy-Open Score Tooling Solutions

Oberg’s Score Tooling supports the creation of easy-open can ends, combining precision and durability to meet both usability and safety standards. With Oberg, manufacturers can achieve high-quality scoring for consumer-friendly products.