- Turbine and engine components, structural parts, precision fasteners

- Power generation components, pump and valve parts, high-performance bearings

- Micro-mechanical components, precision connectors

- Small-Hole tooling

- EDM Powerfeed Tooling

- Fuel system components, transmission parts, EV motor components

- Surgical instruments, orthopedic implants

- Punches and Bushings

- Carbide and Steel die components

Die Design and Engineering Support

Carbide Analysis Lab Support

Machining/Turning/EDM

- Multi-Axis Milling – 3/4/5-axis

- Larg Part Machining – 3/5-axis

- Turning

- Mill/Turn

- EDM Wire and Sinker

- Swiss turn (Chicago plant)

Assembly Cells

- Full automation

- Kitting, Packaging, Labeling

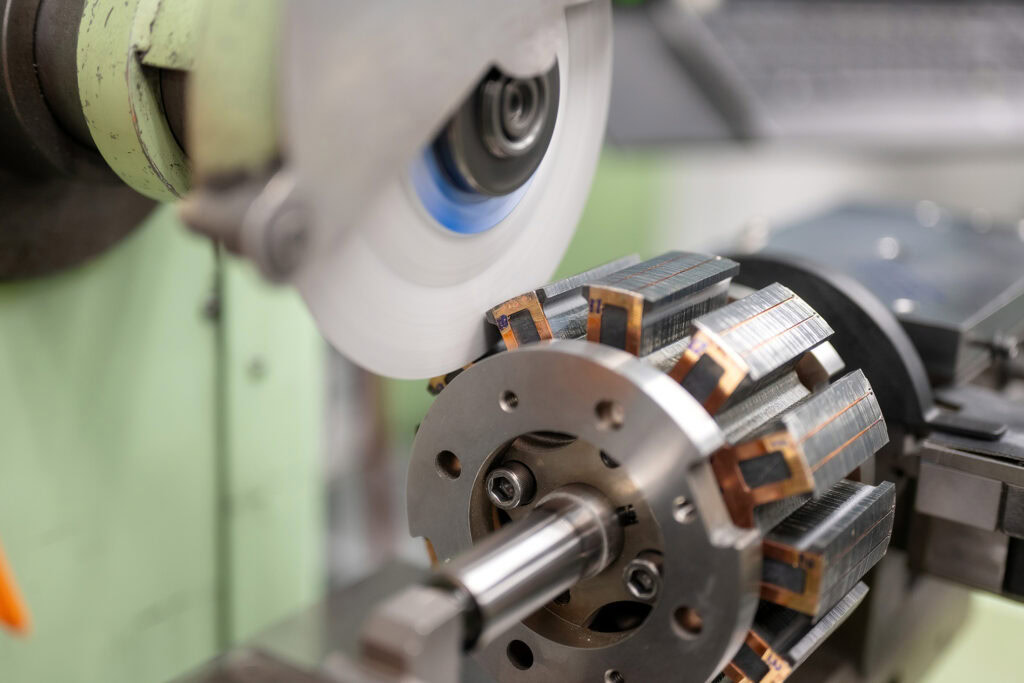

Precision Grinding

- Surface / Centerless

- Advanced Proprietary Grinding (no burrs) MDP

- OD & ID (multi-axis grinding)

- Lapping / Polishing

Special / Secondary Processes

- Heat Treating + Cryogenics – vacuum heat treating and heat treating ovens

- Welding (Laser + TIG)

- Electropolish

- Lapping, Deburring

- CMM Inspection

- Validated Special Processes

Program Management – SPOC

- Tungsten Carbide

- Stainless Steel

- Tool Steels

- Titanium

- Cobalt Chrome Alloys

- Nickel

Oberg offers a complete line of standard size and custom manufactured tungsten carbide punches, matrixes and pilots in imperial and metric dimensions/tolerances. Oberg carbide die components can be manufactured to your print or drawing, regardless of shape or size. Oberg’s precision carbide stamping die components and tooling are recognized by manufacturers around the world for unmatched durability and quality.